Completely Rebuilt Niagara E-250 OBI, Back Geared, Single Crank Mechanical Press. 275 US Tons Capacity, 58" x 36" Bed area, 12" Stroke, 20-60 SPM.

1. Counterbalance Cylinder:

A. Disassemble, clean, and inspect.

B. Review all findings with Rygate Personnel and submit any additional repairs/costs not already included in this quotation.

C. Set up and wet polish cylinder, rods, and pistons to remove any light scoring.

D. Furnish new packings and seals.

E. Reassemble complete and pressure test.

2. Slide Assembly:

A. Disassemble, clean, and inspect all slide adjustment components for wear and dimensional integrity.

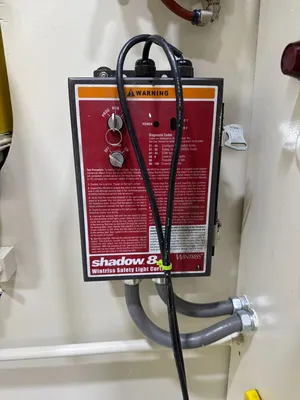

B. Review all inspection findings with Fisher Barton and submit any additional repairs/costs not already included in this quotation.

C. Adjustment nut and housing to be set up and machined accordingly to correct excessive clearance issue.

D. Lower connection has excessive clearance. Replace wrist pin bushing in link, wrist pin and bore adjustment screw to fit new pin if required.

E. Reassemble all components into slide and verify clearances.

F. Test run adjustment motor verifying smooth operation.

3. Slide Assembly; machine bottom of slide assembly, to clean up/parallel. Remove wear strips, and machine grooves in wear strips, and install new wear strips onto slide assembly.

4. Upper Connection/Link Bushing

A. Labor to pull eccentric crankshaft and remove upper connection link.

B. Fisher Barton to provide new Connection arm bushing (will verify that connection arm bushing is to OEM specification first. If it is, will receive new bushing from Fisher and install at Rygate LLC)

C. Once installed, will reinstall crank and fit connection arm to crankshaft.

5. Bolster Plate: Machine top and bottom to cleanup, run end mill through t-slots to clean up and deburr.

6. Reinstall slide assembly into press and secure, level slide and adjust gibs. Install counterbalance cylinders and test run press to verify operation and heat check.

7. Go through and check out lubrication and air systems and make sure everything is in good working order. Replace any damaged lube lines, and check all pumps and motors and make sure in good working condition, and advise. Check lubrication blocks and make sure lube is flowing through all blocks properly.

8. To provide and install a rib for center of opening in bed assembly. Provide and weld into place, to assist in supporting bolster plate.

9. Go Controls to reconnect Wintriss Smart Pac controller and make sure all electrical is in proper working order.

10. As discussed with Tom; ordered 12 new brake studs, for the brake assembly, after disassembly and inspection of the brake. Everything else in the brake assembly checked out and looked to be in good condition.

Brake Stud

Labor to dismantle brake, install, and reassemble

11. New Flywheel and Driveshaft Bearings

a. Labor for dismantle and removal and reassemble

b. Repair Bearing Housing

Estimated Delivery: 10-12 Weeks

250 Metric Tons Capacity

275 US Tons Capacity

12" Stroke

28" Shut Height

6" Slide Adjustment

58" LR x 36" FB Bed Area

48" LR x 30" FB Slide Area

20-60 VSPM

Air Clutch and Brake

Air Counterbalances

Recirculating Lube System

T-Slotted Ram and Bolster

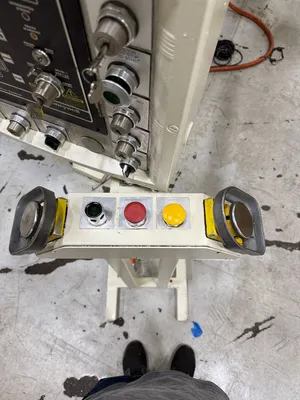

Palm Buttons

4" Thick Bolster

Air Cushion

Motors and Controls

We use cookies to improve your experience. Privacy Policy.